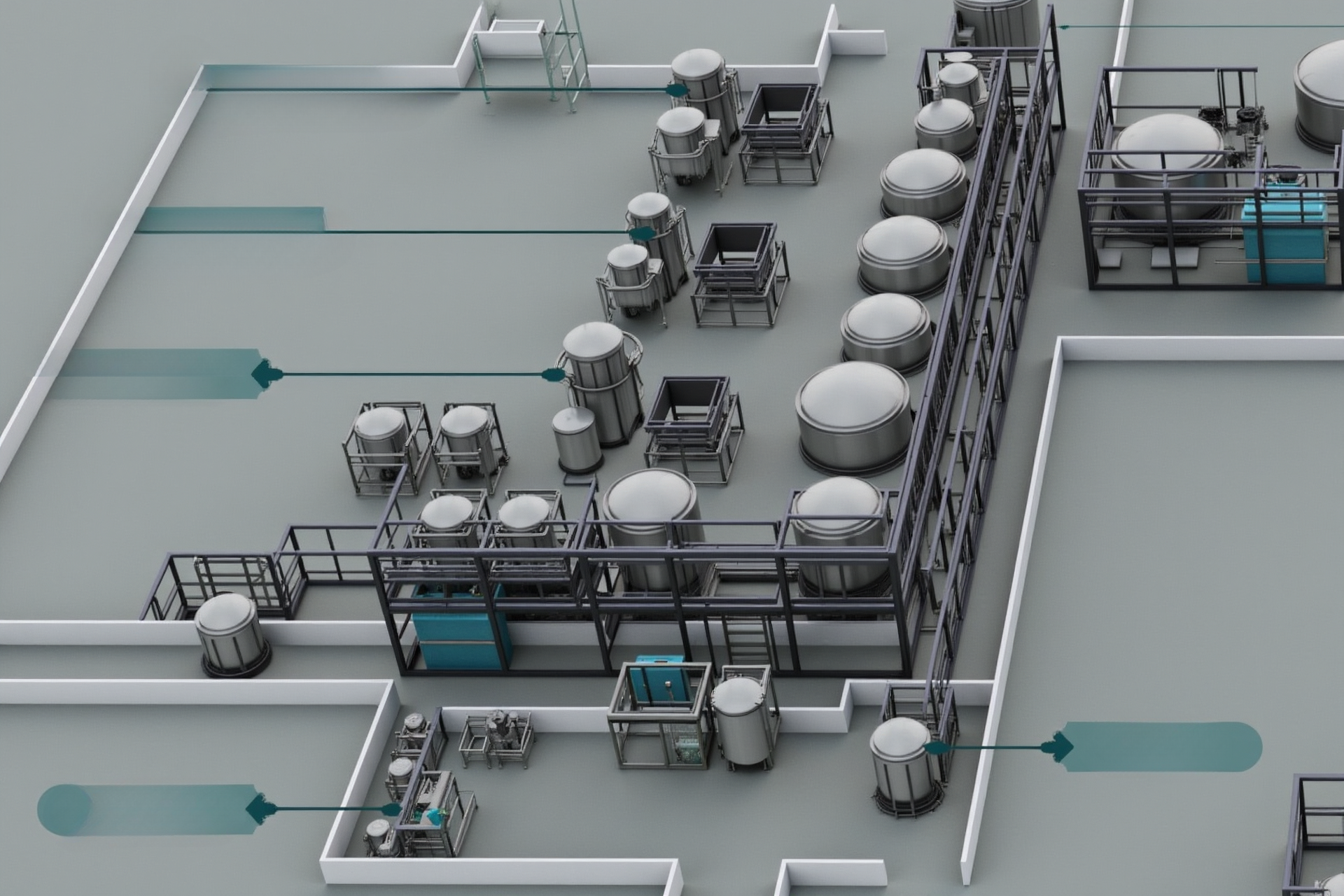

提供了一套基于Stratus ftServer的虚拟化SCADA解决方案,通过Siemens WinCC系统来实现对三抗上下游车间各个工艺单元的自动化系统的实时3D画面显示,关键信息收集,报警处理,历史数据归档,数据库备份,时间同步以及大屏显示等功能,并完成对PCS7系统的历史数据的迁移验证WinCC系统采用OPC DA通讯协议来实现对Siemens平台的工艺设备(生物反应器,除病毒过滤超滤,BMS,水系统等)的实时数据采集及报警处理,采用OPCUA通讯协议来实现对DeltaV平台的工艺设备(层析和在线配液)的实时数据采集及报警处理。

A virtualization SCADA solution based on Stratus ftServer has been provided, utilizing the Siemens WinCC system to achieve real-time 3D visual display of various process units in the upstream and downstream workshops of the three-resistance production line. This solution enables key information collection, alarm handling, historical data archiving, database backup, time synchronization, and large screen display functionalities, as well as completing the migration and validation of historical data from the PCS7 system. The WinCC system employs the OPC DA communication protocol for real-time data acquisition and alarm processing of process equipment on the Siemens platform (such as bioreactors, virus removal filtration ultrafiltration, BMS, water systems, etc.), and uses the OPC UA communication protocol for real-time data acquisition and alarm processing of process equipment on the DeltaV platform (such as chromatography and online liquid preparation).

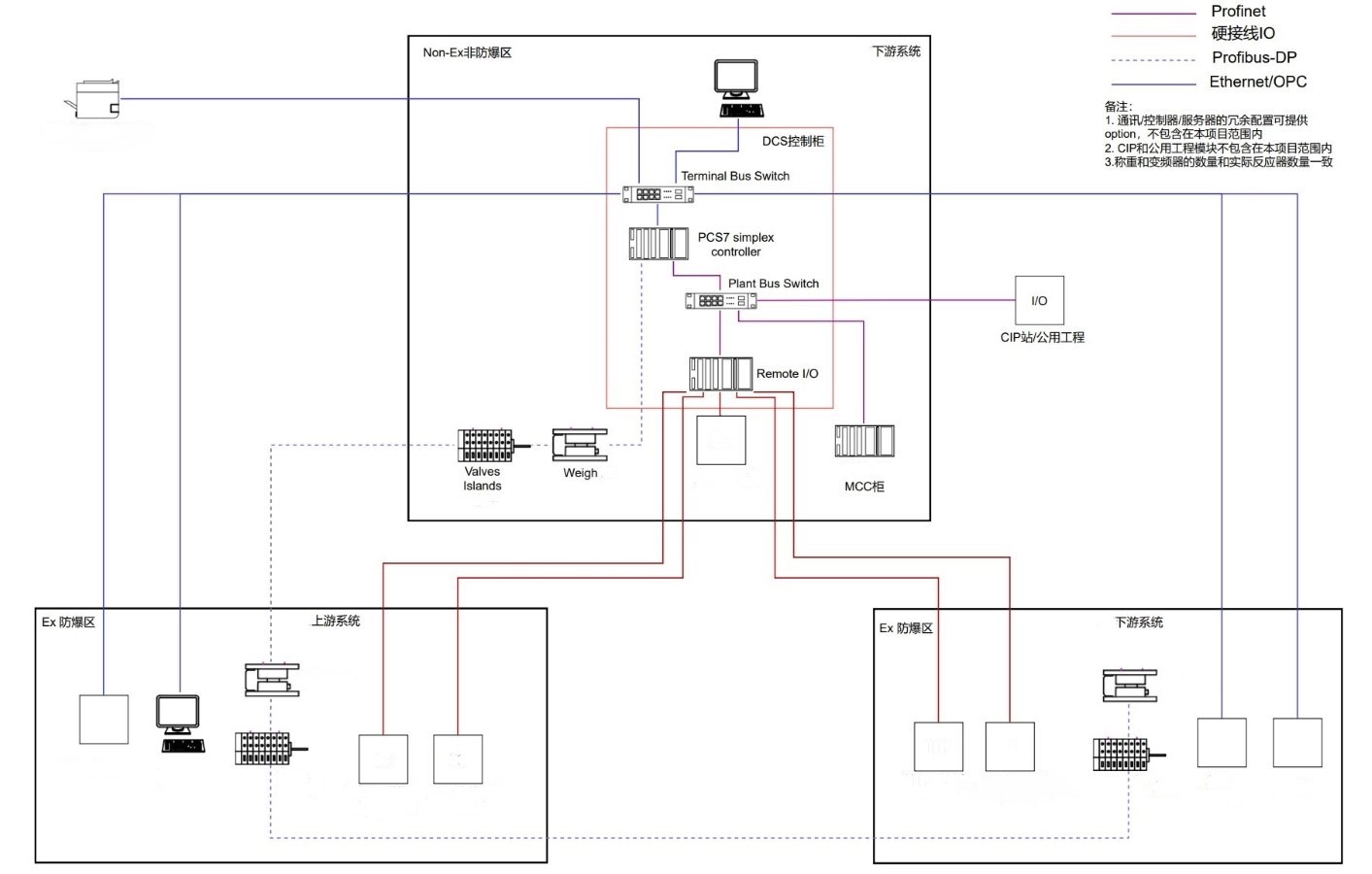

提供了一套基于Siemens PCS7平台的自动化演示系统来实现对寡核苷酸生产用管罐系统的批量自动化控制,来完成裂解、脱保护、淬灭以及退火反应,并将相关合成仪、层析和超滤等第三方设备的实时数据集成到此平台上。

该系统硬件基于S7-410 Smart CPU, 搭配ET200SP及对应AI, AO, DI, DO等卡件。该系统采用服务器/客户机架构,集成OS服务器,Batch服务器,OS客户机,Batch客户机在两台IPC上,其中1台客户机为防爆IPC。

提供了完整了质量管理文档,在PCS7系统上配置电子签名,审计追踪,用户管理,数据安全性等GAMP相关功能,并完成相关CSV验证。

A demonstration automation system based on the Siemens PCS7 platform has been provided to achieve batch automation control for the tank system used in oligonucleotide production, facilitating processes such as cleavage, deprotection, quenching, and annealing reactions. The system integrates real-time data from third-party equipment like synthesizers, chromatography, and ultrafiltration onto this platform.

The system's hardware is based on the S7-410 Smart CPU, paired with ET200SP and corresponding AL, AO, DI, DO cards. It adopts a server/client architecture, integrating OS server, Batch server, OS client, and Batch client on two IPCs, one of which is an explosion-proof IPC.

Complete quality management documentation has been provided, configuring the PCS7 system with electronic signatures, audit trails, user management, data security, and other GAMP-related functions, and completing the relevant CSV validation.

提供了一套基于Stratus ftServer的虚拟化SCADA解决方案,通过Siemens WinCC系统来实现对中试车间及原液上下游车间各个工艺单元及辅助共用工程设备的自动化系统的实时3D画面显示,关键信息收集,报警处理,历史数据归档,数据库备份,时间同步以及大屏显示等功能,并完成对历史数据备份的验证。

在WinCC平台之上,配置有数据管理平台,可以实现对WinCC系统采集的数据做数据统计分析,并通过各种报表,趋势图等工具展示工厂及车间运行状态。

WinCC系统采用OPC DA通讯协议来实现对Siemens平台的工艺设备(生物反应器,除病毒过滤超滤,BMS,水系统,罐装系统等)的实时数据采集及报警处理,采用OPCUA通讯协议来实现对DeltaV平台的工艺设备(中试车间管罐系统、原液车间层析和在线配液)的实时数据采集及报警处理,采用Modbus TCP通讯网关来实现对现场水表,电表,蒸汽计量等共用设备的数据采集及报表统计。系统集成各个楼宇的分布式CCTV和WinCC平台为一体,集中显示到中控室大屏上。

A virtualization SCADA solution based on Stratus ftServer has been provided, utilizing the Siemens WinCC system to achieve real-time 3D visual display of various process units and auxiliary shared utility equipment in the pilot and bulk drug upstream and downstream workshops. This solution enables key information collection, alarm handling, historical data archiving, database backup, time synchronization, and large screen display functionalities, as well as completing the validation of historical data backup.

The WinCC system employs the OPC DA communication protocol for real-time data acquisition and alarm processing of process equipment on the Siemens platform (such as bioreactors, virus removal filtration ultrafiltration, BMS, water systems, filling systems, etc.), and uses the OPC UA communication protocol for real-time data acquisition and alarm processing of process equipment on the DeltaV platform (such as the pilot workshop tank system, bulk drug workshop chromatography, and online liquid preparation). The Modbus TCP communication gateway is used for data acquisition and report statistics of on-site water meters, electricity meters, steam meters, and other shared equipment. The system integrates distributed CCTV from various buildings with the WinCC platform, displaying them centrally on the large screen in the control room.

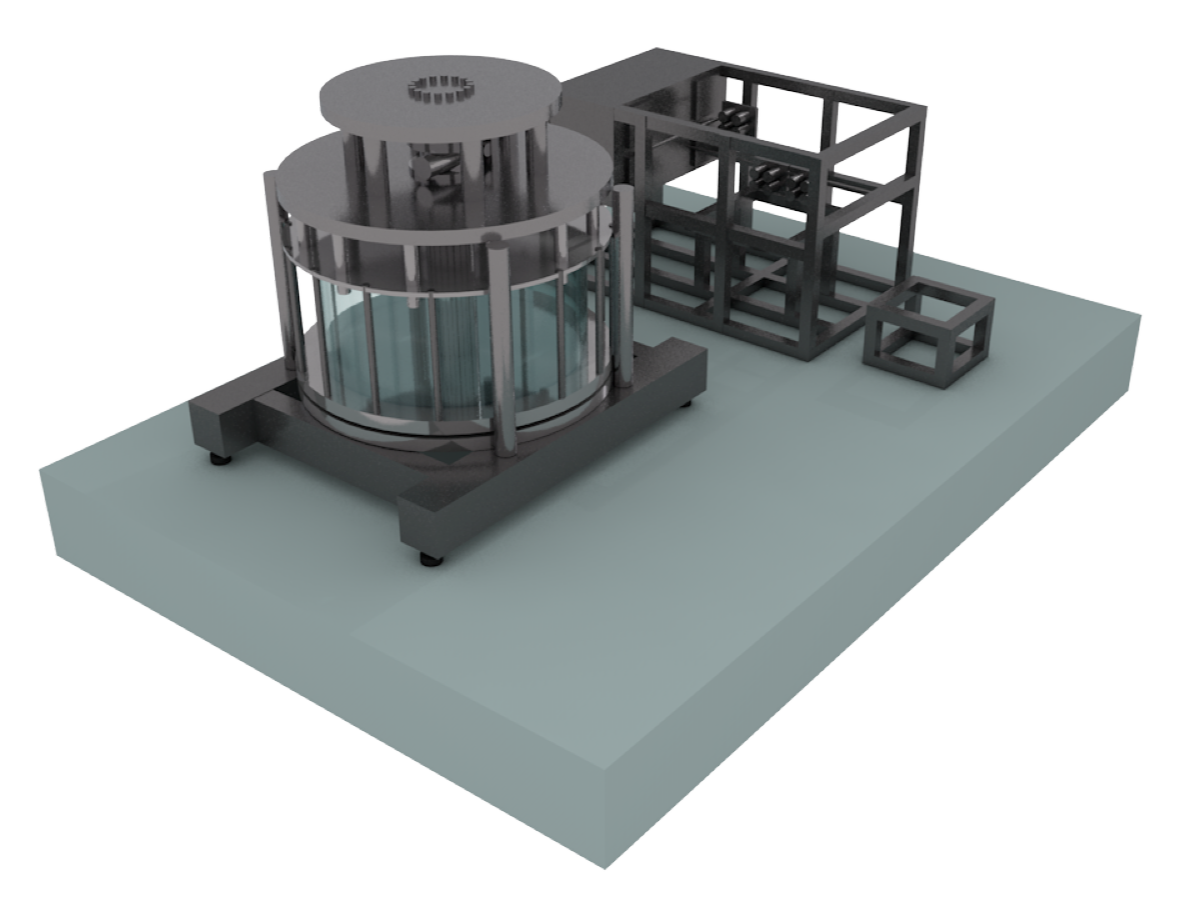

胰岛素车间6t细胞培养下游管罐系统项目,该项目使用一套分散控制系统用来控制和监控如下系统数据:缓冲液配制模块、缓冲液存储模块、粗存模块、深层过滤设备、除病毒设备、超滤模块、下游CIP站。

在技术上我们采用了主流服务器虚拟化平台,可以更好的进行集中化管理,并提高硬件利用率及高可靠性。

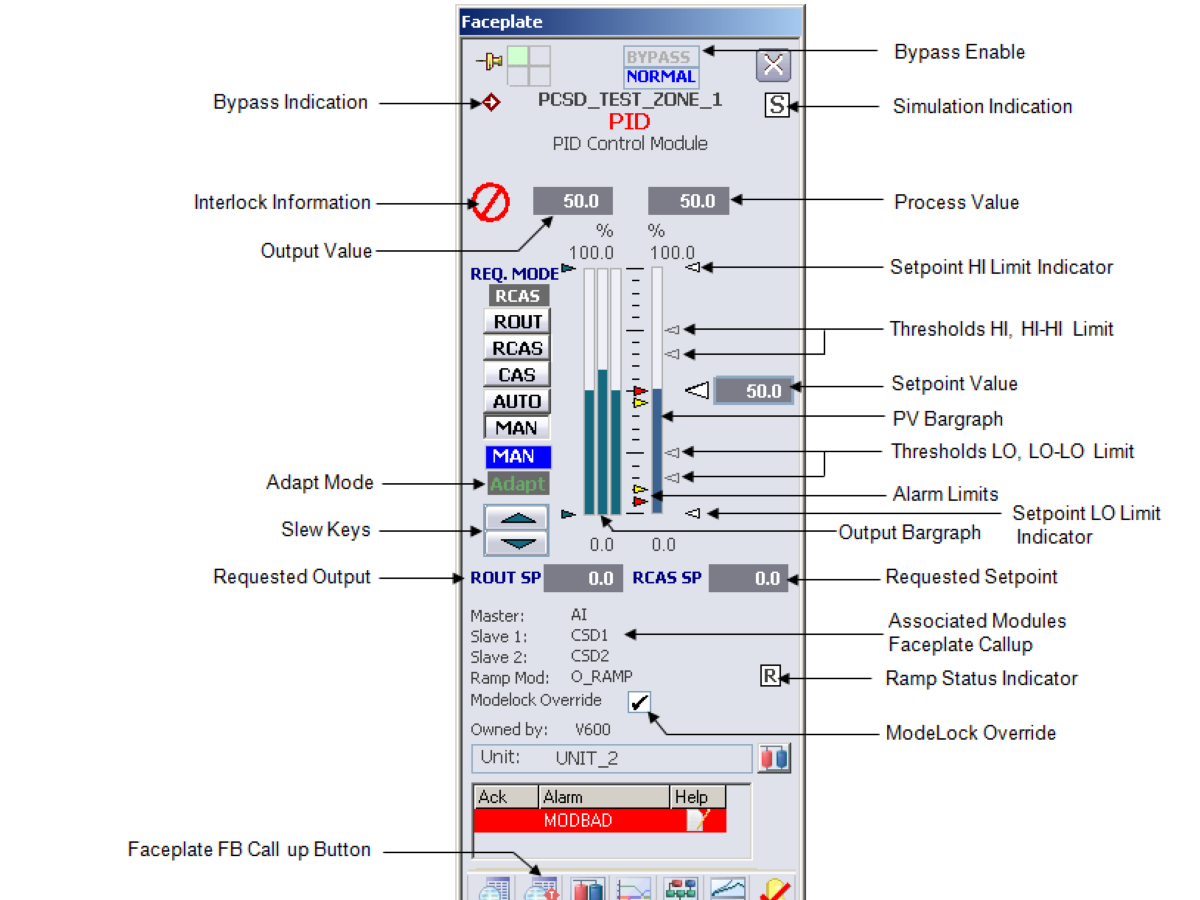

软件上采用Emerson DeltaV Batch, 完全符合ANSI/ISA 88批处理控制标准,并基于类的概念创建单元类、phase类、EM类和CM类。

人机界面上使用DeltaV Live用于生产过程管理和监控的画面,包括以下主要部分:总貌、工艺流程、过程单元、批次界面,建立更友好的操作界面。

The Insulin production workshop 6T Cell downstream tank system project employs a distributed control system to monitor and control the following system data: buffer preparation module, buffer storage module, crude storage module, depth filtration equipment, virus removal equipment, ultrafiltration module, and downstream CIP station.

Technologically, we have adopted a mainstream server virtualization platform, which allows for better centralized management and improves hardware utilization and high reliability.

On the software side, Emerson DeltaV Batch is utilized, fully compliant with the ANSI/ISA 88 batch processing control standards, and creates unit classes, phase classes, EM classes, and CM classes based on the concept of classes.

For the human-machine interface, DeltaV Live is used for the management and monitoring screens of the production process, including the following main parts: overview, process flow unit, batch interface, to establish a more user-friendly operation interface.

项目内容涉及:

1. 增加生产前检查PHASE,确保了在生产开始前完成所有必要的检查工作并符合相关标准。

2. 增加批记录中的流速控制,并将流速控制数据集成到批记录中,以便追踪和分析生产过程中的流速变化情况。

3. 增加批报告参数,确保新增的批报告参数能够准确地反映产品的质量和生产过程的稳定性。

4. 对接批报告数据,与MES系统开发商协作,将批报告数据集成到MES系统中,以便进行后续的数据分析和处理。

The project content involves:

1. Adding a pre-production inspection PHASE to ensure that all necessary checks are completed and comply with relevant standards before production begins.

2. Incorporating flow rate control into the batch record and integrating flow rate control data into the batch record to track and analyze flow rate variations during the production process.

3. Adding batch report parameters to ensure that the new batch report parameters accurately reflect product quality and the stability of the production process.

4. Interfacing batch report data, collaborating with the MES system developer to integrate batch report data into the MES system for subsequent data analysis and processing.